Important point to consider when choosing the right Pedestrian and Vehicle access gate for your business: IK rating

The following paper highlights what aspects need to be considered when deciding which pedestrian and vehicle products to purchase. One of those is related to the robustness of the equipment, and the way the manufacturer complies to international norms on that matters, including IK impact protection rating.

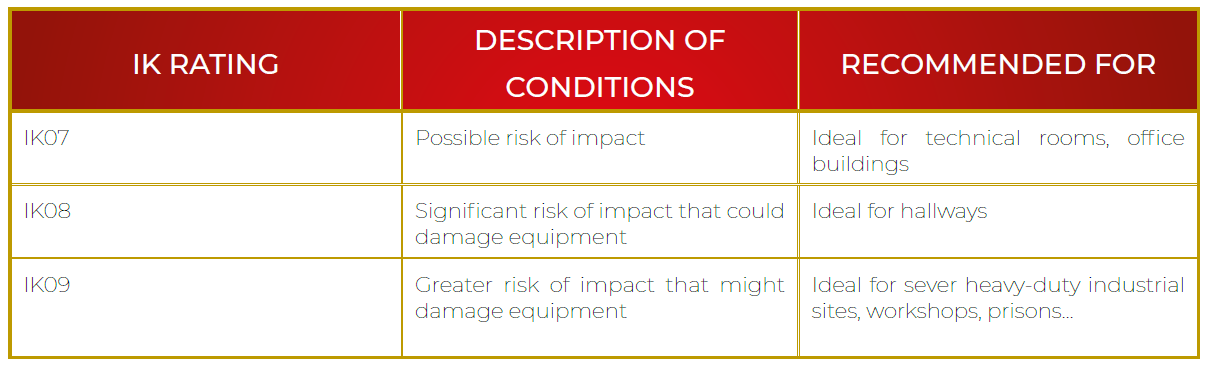

IK Rating or “Impact Protection” is defined in international standards and indicates the level of resistance an electrical enclosure provides against mechanical impact. The key question to consider when choosing the right pedestrian and/or vehicle access gate is what do you want to accomplish as an end result?

- Ensure competitive advantage in invitations for tender?

- Improve brand image?

- Present technology dominance?

- Increase resilience?

- Improve product lifespan?

But up to which limit the effort is worth depends on the application? The impact resistance and test methods are defined by EN 62262, by the “IK” class.

From class IK07 the energy gain per level increases by more than 100%. After the IK07 class the efforts and costs are equal as the impact on energy (in Joule) is growing exponentially. For instance, if we use a smartphone with a Corning® Gorilla Glass 5 as an example, it is about IK07 class. Gorilla Glass 5 is engineered to better survive drops from the worldwide average waist height. In lab tests, it successfully survives up to 1.2m drops onto rough surfaces, while still maintaining the superior scratch performance.

Weight of generic smartphone = 0,174kg

Corning Gorilla Glass 5 = no break if dropped form 1,2m

J = 0,174*9,80*1,2 = 2J

2J = IK07

IK08 – this is almost at the highest level which should satisfy all users looking for an armored smartphone. Grade IK08 corresponds to a 1.7 kg steel hammer or ball impact from a height of 29.5cm on a housing (each external side of the housing is impacted). This high value of IK can prevent us from having to change our smartphones as a result of dropping and crushing which are the most common causes of damage.

Ultimately you need a product that’s sufficiently highly resistant if there is a chance it can be exposed to significant risk of impact from IK07 to IK09-rated products.

It is important to decide on the appropriate enclosure for your needs to avoid extra cost or work in later stages. Therefore, choosing a right enclosure early on in the design process can save in design cost and product assembly time, while ultimately at the same time reduce product failures and claims.

HOW TO IMPROVE IK-RATING

The four main ways for improving impact rating can be found below:

- Material – Choosing material which has great properties against impacts

- Thickness – Increase material thickness of the enclosure

- Shape – Design the enclosure shape so that it deflects impacts or disperses the impact energy to a wider area

- Low IP-rating – Applying lower IP (or NEMA) rating allows the enclosure to deform more during the impacts and still pass the tests

For higher IK-rating you normally need to make some compromises: encounter a higher initial price for the enclosure as a result of better raw material or lower IP-rating. Raw material is the single most important factor when aiming for high IK-rated enclosures. The best three enclosure materials are stainless steel, glass reinforced polyester and polycarbonate:

- Stainless steel is the most expensive material but has the best impact resistance.

- Glass reinforced polyester is extremely strong but is prone to UV-radiation and is non-recyclable.

- Latest technological advances have allowed polycarbonate to join this group – Polycarbonate is a UV-resistant, non-corrosive material which can be recycled.

Typically, a thicker enclosure wall improves the durability of the enclosure. Corners are usually the weak points and therefore round shapes allow impact energy to be deflected from energy or dispersed to a larger area. A round shaped enclosure has typically a better chance of withstanding the impacts than a similar enclosure with sharp corners.

TO CONCLUDE

It is important you look very closely to the application of the product and whether it is exposed to rigorous use and impacts. If your requirements are for a more durable performance, ensure you analyse to get the best quality to cost ratio for your product. It is also very important to also take into consideration the environment where the product will be sited. All of these factors put together will have an effect on your product performance.

Ultimately you are looking to choose a durable product with a long lifespan that protects your integrations and saves money at the same time. Choose smartly and wisely!

Automatic Systems products are up to IK09 rated, of native design and tested to perform!